Premium Custom Metal Tin Packaging for Global Brands

High-quality tin boxes designed for Food, Beauty, Gift, and Industrial applications—crafted with precision, creativity, and world-class manufacturing standards.

4.9

1,458 reviews

Mr. Tin Box

Trusted Brand

Delivering proven reliability through an unwavering commitment to quality. Your peace of mind is our promise.

Key Industries

Food & Beverage Packaging

Beauty & Personal Care Packaging

Gift, Promotional & Holiday Packaging

Specialty & Industrial Packaging

Our Impact in Numbers

Driving success for 1K+ customers with 1,200+ products, all backed by over a decade of proven expertise.

0

Years of Experience

0

Square Meters of Factory Area

0

Outstanding Staff

0

Product Types

Food & Beverage Packaging

Safe, airtight, and food-grade certified tin boxes for tea, coffee, snacks, confectionery, and specialty foods.

Beauty & Personal Care Packaging

Luxury metal boxes designed for perfumes, skincare sets, essential oils, and premium cosmetic products.

Gift, Promotional & Holiday Packaging

Creative, high-impact packaging solutions for seasonal gifts, corporate promotions, and brand campaigns.

Specialty & Industrial Packaging

Precision-engineered tins for tools, electronics, tobacco, pharmaceutical products, and collectibles.

With a fully-equipped production facility, advanced tooling workshop, automated stamping lines, and professional finishing systems, we deliver reliable and consistent metal packaging for global brands.

Why Brands Choose Our Metal Packaging

4.9/5

We combine advanced manufacturing technology with refined craftsmanship to deliver metal packaging solutions that strengthen brand identity, ensure product safety, and exceed quality expectations for global markets.

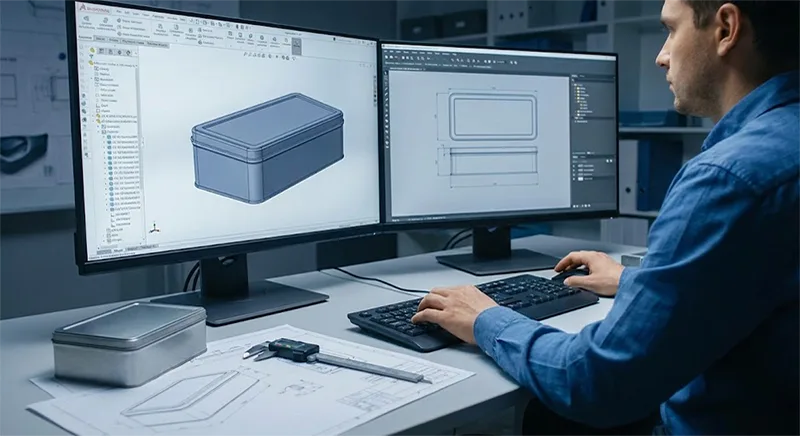

How We Create Your Custom Metal Packaging

Every custom tin project follows a precise engineering and production workflow to guarantee exceptional quality, perfect functionality, and on-time delivery.

Step 1 — Consultation & Requirements

We review your project details: size, shape, artwork, structure, and application.

Step 2 — 3D Drawing & Structure Design

Our engineers create custom 3D designs with exact dimensions and functionality.

Step 3 — Mold Development or Sample Making

Rapid sampling within 7–10 days to verify structure and finishing.

Step 4 — Printing & Surface Finishing

Color matching, varnishing, embossing, foil stamping, and more.

Step 5 — Stamping & Assembly Process

Automated forming ensures consistency across large production volumes.

Step 6 — Quality Inspection & Packaging

Final QC checks for appearance, sealing, alignment, and durability.

Ready to Create Your Custom Metal Packaging?

Get professional guidance, free samples, and fast quotations for your next project.